HIGHLY EFFICIENT

JK-L2700 Legender

15 CVT BLOCK MAKING PLANT

JK-L2700 Legender 15 CVT Block Making Plant

The Endmost Concrete Product Solution with 7th generation FCCT – VIBRO HYDRO TECH.

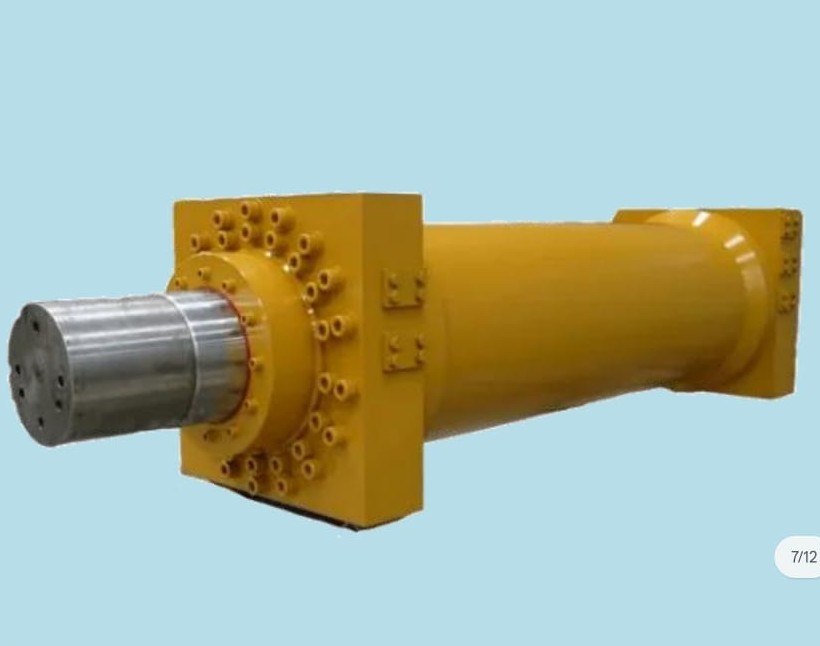

Major Components of Block Making Machine

Main Machine & Technology

SPECIFICATION

- Heavy MS steel plate Body 22 to 25mm thickness, Hydraulic Main jack & Two Side cylinder with Hydraulic oil seal Technoland / Rajhans.

- 330 to 350 Tones Pressure with Vibration, Automatic Feeder facility, Sensor System Machine, Auto. Stacking system & Auto. PLC based Comp. Panel board system.

- Hose Pipes 4sp Parker

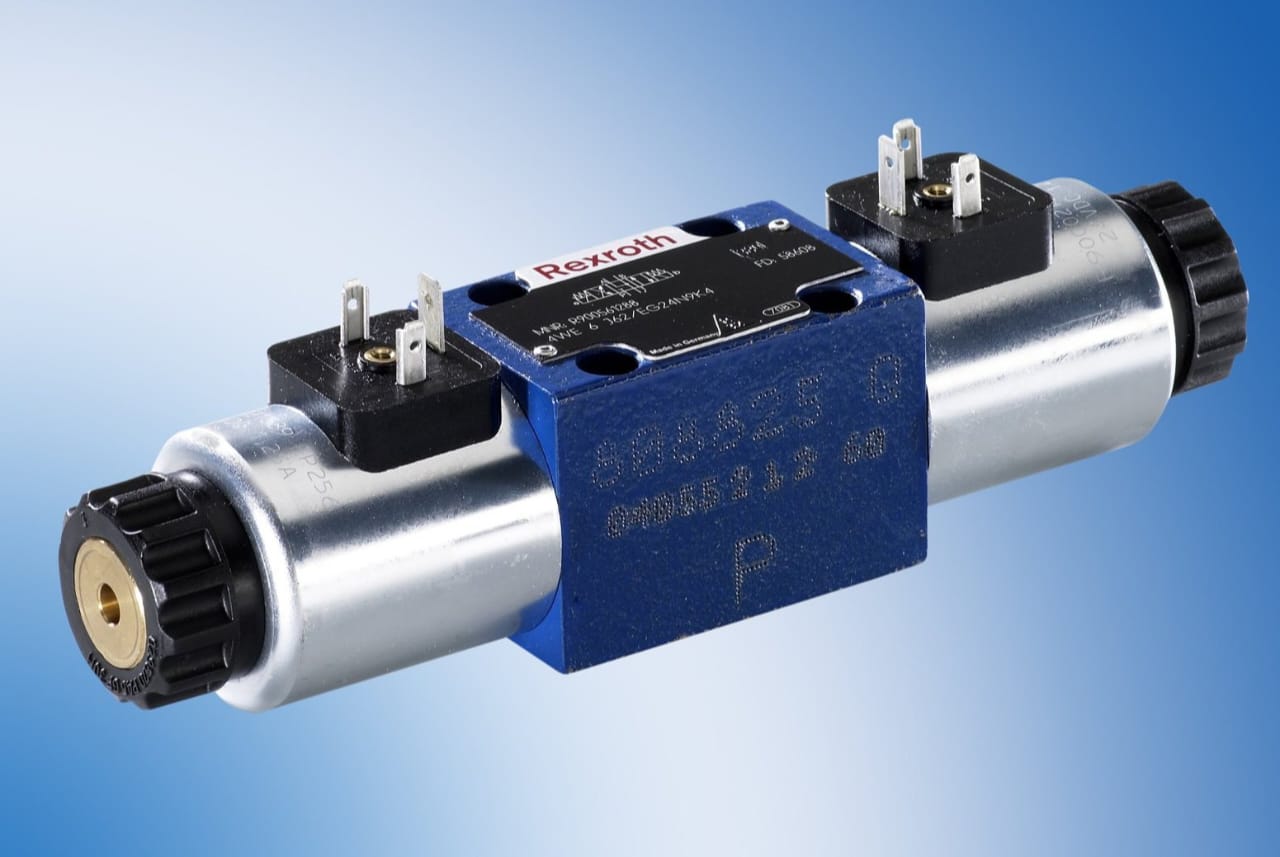

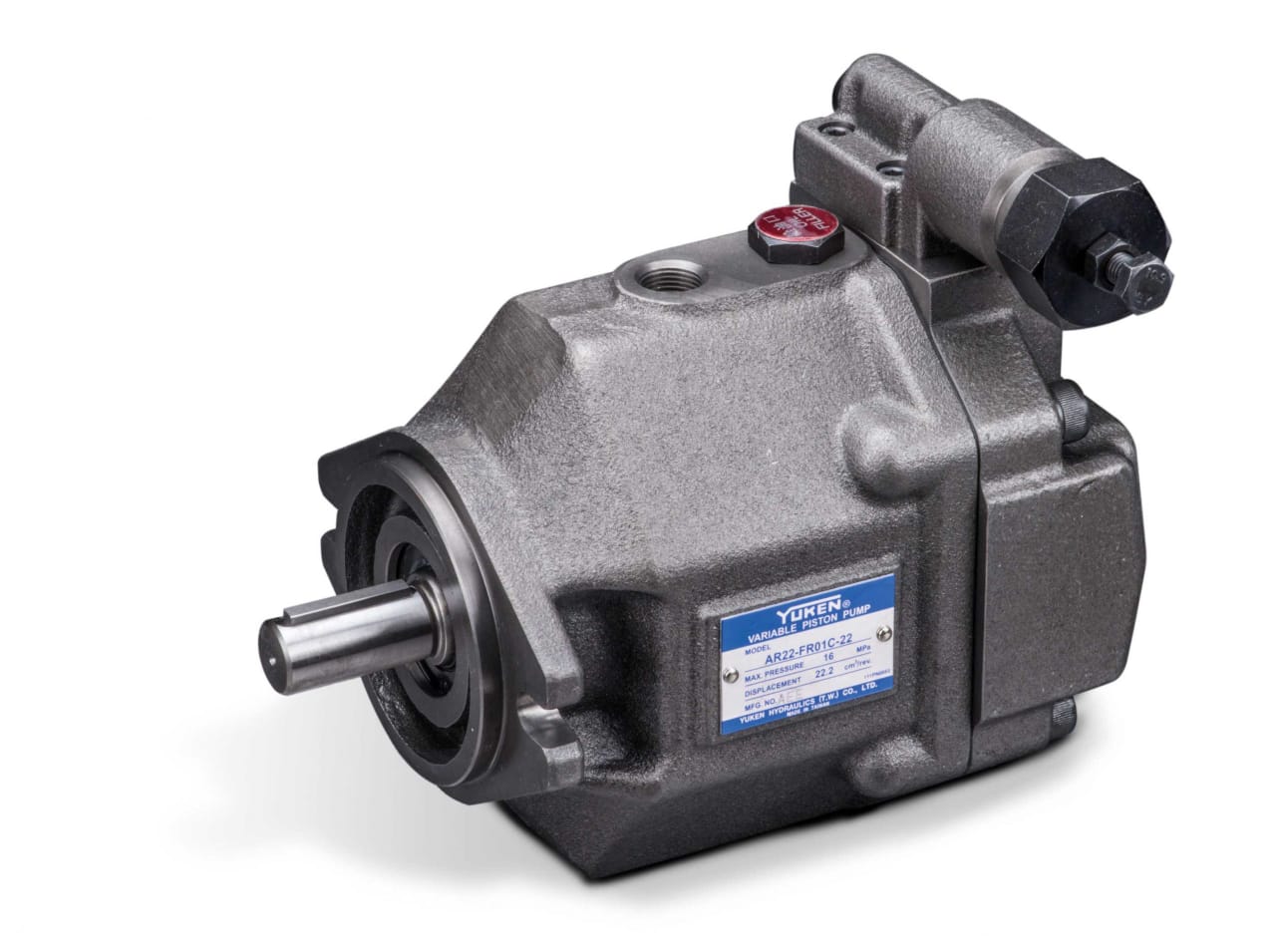

Power pack

SPECIFICATION

- Hydraulic Pressure 330-350 Tonnage.

- 20 HP JKTM Motor(Own Brand) For Main power pack with copper winding.

- 700 Liters Oil Tank with Oil Cooling System.

- Yuken® Plunger Pump.

- Pressure Meter Scientific/Micro.

- Sonoligh Control Valve Rexorth.

- Bosch Speed Gear Pump.

- Hydraulic Jack Oil Seal Technoland/ Ranjhans.

Automation PLC Panel With Remote control (for Main Machinery plant)

SPECIFICATION

- (EPCS)Electronic Pressure Control System.

- MS Steel Sensor System With Auto Stop Facility.

- (HSCS) Hydraulic Speed Control System.

- Electronics Parts By Siemens® & Delta.

- Dust & vermin proof Panel suitable for bottom cable entry.

- Wecon / Delta / Schneider / Siemens / Excella etc.

PLC Unit For Fully Auto Batching Plant

SPECIFICATION

- Other Important Features :- Electronics pressure control volume system. - MS steel sensor system with Auto stop facility. - Hydraulic speed control system & Vibrator control system. - Emergency Button, Stroke calculator, Delay Timer, LED & Display. - Facility to operate the machine in Automatic & Semi Auto. - Electronics parts Siemens, Schneider and Delta. - Panel is dust and vermin proof, suitable for bottom cable entry. - Each motor feeder have a MCCB(35KA) for overload and short circuit protection.

Conveyer belt System

SPECIFICATION

- Dimension(Belt) : 6600mm X 450mm X 10mm

- motor : 3 HP

- Gear Box : 3 liters

- To feed the mix from the pan mix to the Brick, Press: Capacity 2 Tons / hour Power (Motor) Bottom End 2 hp. 1440 RPM Crompton motor Storage intermittent Bin flow Regulation By heavy rollers Gear Box 300 - 30 *1 RPM

Auto Stacker System

SPECIFICATION

- Automatic pallets stacking system for smooth & speedy operation.

- Power require5 HP (1 Hp + 1 Hp + 1 Hp).

- Hydraulic Lifting system for running the stacker.

- Controlled by variable frequency drive

Color mixer Machine

SPECIFICATION

- Capacity : 100 kgs to 125 kgs / Per Batch Power (Motor): 2 Hp. – 1440 rpm Crompton/Havells Motor Manufacturing: Mixing of raw Materials of Top Layer Rubber Mould, Paver Block.

Hydraulic Trolley

SPECIFICATION

- Hydraulic Trolley Manufactured using high-grade raw material, These Trucks are known for their high performance, Durability, strong construction and low maintenance. - Hand operated Hydraulic system.

Twin Shaft Pan Mixer Machine

SPECIFICATION

- High robustness and reliability. Identical and interchangeable anti wears liners and Blades with high chrome alloy steel.

- Effective mixing characteristics in radial, vertical and circular directions.

- Heavy duty Gear Box with Motors.

- End Arm Paddle with Hard Facing.

- Reduced wear with aerofoil Arm Design.

- 20 HP Crompton / Havells motor.

- Mixer Body Full Machining on Boring Machine for Complete Allignment. Hydraulic door open system with Small Power-pack & 2Hp motor.

Batching Plant with Complete set (Three bin system & Cement Hopper)

SPECIFICATION

- MS Steel Plate 6mm use for Mfg. of Batching Plant with Three Bin Hopper (5500kg. to 6000kg. capacity each) facility for different types of Material mixing with Proper Ratio,

- Power: 5 Hp in Main Conveyor Belt motor, 1Hp Vibro. motor in Three hopper Jar (3 Hp), 1Hp Vibro. motor in Three hopper (3 Hp), 1Hp motor in Three Small conveyor belt (3 Hp) & 3 Hp for Main conveyor belt from batching to mixer machine, So Total Power required 17Hp.

- Electronics control system with Auto. Weight Load cell, Load cell conveyor size 800m × 10m (24feet).

- Rigid construction of main chassis fabricated from rolled mild steel material.

- Cement storage hopper type Scrue conveyor 15 vertical type 2Hp motor with gearbox.

- Loading of Aggregate/Sand Hoppers by Wheel loader/ Conveyors/ Manually.

- MS steel sensor & Vibrator control system.

Major Parts of Block Making Machine

PRODUCT SPECIFICATION

| No | JKSAT-BlockMaster 1150 Single Stroke | Production Type |

|---|---|---|

| 1 | Overall Dimension | 1800mmL x 1280mmW x 1890mmH |

| 2 | Total Power | 8.5HP |

| 3 | Vibration Suspension Ty | Anti Vibration JK Rubber Paded U Mounting Brackets |

| 4 | Vibration Frequency | 70-80 Heartz (Hz) |

| 5 | Cycle Time per minute | 40 to 45 secs per mould |

| 6 | Sheet Thickness | 8 MM Top Sheet Thickness/ Bottom Plate 12 MM/side Plate 8 MM |

| 7 | Power Supply | 3 Phase Commercial Connection. |

| 8 | Maximum Block Height | Variable Depends On Product |

| 9 | Automation Grade | Semi Automatic+manual |

| 10 | End Production Type | Paver Block, Cement Tiles, Concrete Block, Parking Tiles, Interlocking Tiles Etc. |

Final Products

Hollow Block

Flyash Brick

Kerb Stone

Zig Zag Paver

I Shape Paver

Solid Block